When driving on an unlit backroad at night, the quality of your vehicle’s lighting is the single most critical safety factor. Many enthusiasts look to the engineering standards set in central Europe as the benchmark for precision. Just as a high-end, tactical flashlight germany is renowned for its robust build and incredibly focused beam without wasteful spill, automotive lighting should aspire to the same level of optical control. This guide explores how modern LED projector lens technology allows vehicles to achieve that gold standard of illumination, transforming scattered photons into a precise, tactical driving tool.

1. Understanding Automotive Optics: Reflectors vs. Projectors

To understand why many LED upgrades fail to impress, we must first understand the basic principles of automotive optics. It is not enough to simply generate light; that light must be directed.

1.1. The Traditional Reflector Bowl

For decades, cars relied on reflector headlights. A bulb (usually halogen) sits in the middle of a chrome-plated bowl. The light shines 360 degrees, hits the bowl, and is bounced forward. This system relies entirely on the precise location of the bulb’s filament. When you replace a halogen bulb with a standard LED stick that has chips in a slightly different position, the optical geometry is broken. The result is often a flood of unfocused light—bright near the car, but lacking distance, and creating significant glare for oncoming traffic.

1.2. The Projector Lens Revolution

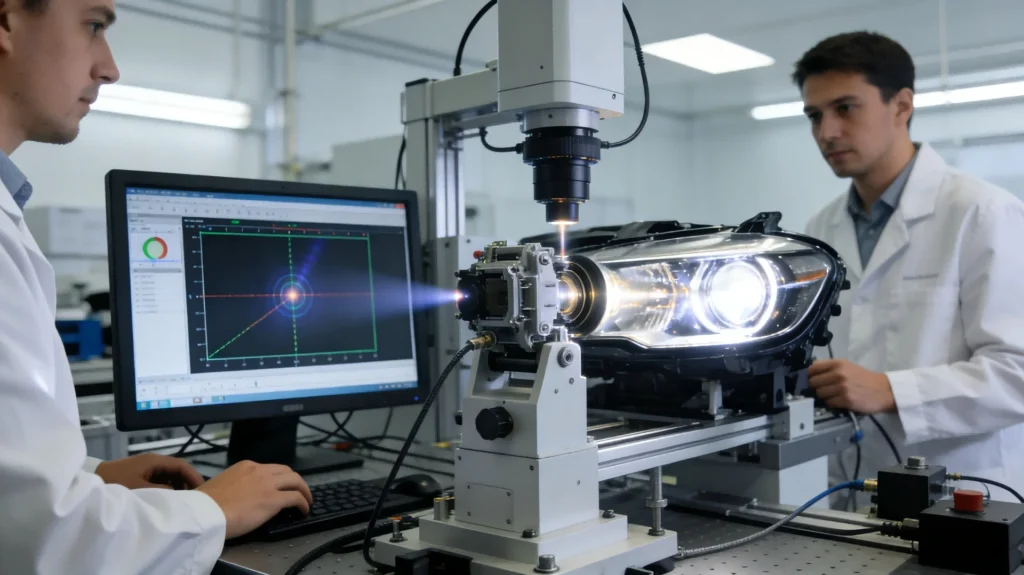

Thinking back to the analogy of a high-quality bti flashlight germany or similar precision tools, the secret lies in the lens. A projector headlight system works like a slide projector.

- **The Light Source:** A powerful LED chip generates the light.

- **The Reflector Bowl:** A smaller, elliptical bowl gathers this light and directs it towards a focal point.

- **The Cutoff Shield:** This is crucial. A physical metal shield sits between the reflector and the lens, blocking the lower half of the light beam. This creates the sharp horizontal “cutoff” line you see on modern luxury cars, keeping light out of oncoming drivers’ eyes.

- **The Lens:** A convex glass lens magnifies and projects this perfectly shaped beam down the road.

The advantage of companies like GTR is that they focus on this entire optical system. By utilizing integrated mini-projector LED bulbs, you are not just upgrading the light source; you are upgrading the entire optical engine of your headlight assembly to achieve a standard often associated with precision flashlight made in germany engineering.

2. Core Application Scenarios for High-Precision LEDs

While every vehicle benefits from better lighting, certain scenarios demand the optical superiority that only lens technology can provide. High-performance lighting is not merely cosmetic; it is a functional necessity in demanding environments.

2.1. High-Speed Highway Driving (The Autobahn Scenario)

At speeds over 60 mph (100 km/h), your reaction time depends entirely on how far down the road you can see. Standard reflector LEDs often suffer from “foreground flooding”—they make the ground right in front of the car very bright. This causes your pupils to constrict, actually reducing your ability to see into the darkness ahead. A precision projector beam throws light hundreds of feet further, giving you crucial seconds to react to obstacles. This long-range throw without blinding others is the hallmark of quality engineering.

2.2. Adverse Weather: Fog, Rain, and Snow

This is where the “tactical” aspect comes into play. In fog or heavy rain, bright, uncontrolled light hits the water droplets and reflects straight back into the driver’s eyes—a phenomenon known as backscatter. A scattered beam from a cheap LED makes visibility worse in fog.

A high-quality LED projector, particularly in fog light applications, creates a flat, wide bar of light that stays low to the ground, cutting *under* the fog layer. The sharp cutoff prevents light from bleeding upwards into the falling rain or snow, significantly improving contrast and visibility. This controlled output is akin to the difference between a cheap floodlight and a specialized tactical flashlight germany designed for specific operations.

3. Module 3: Key Buying Factors – Moving Beyond Lumen Hype

The automotive lighting market is saturated with misleading specifications. Browsing forums and Reddit threads reveals immense confusion over which specifications actually matter. To make an informed choice, you must look past the marketing numbers on the box.

3.1. Lux vs. Raw Lumens (The Truth About Brightness)

This is the most important concept to grasp. “Lumens” is the total amount of light emitted by the source in all directions. It is easy for manufacturers to inflate this number. “Lux” is the amount of usable light that actually arrives at a specific point at a specific distance.

You could have a 20,000-lumen bulb in a reflector housing that scatters light into the trees, putting very little lux on the road 100 feet away. Conversely, a precision-engineered 6,000-lumen GTR projector lens can focus nearly all its output exactly where needed, resulting in a far higher lux reading on the asphalt. You want usable lux, not theoretical lumens.

3.2. Beam Pattern and Cutoff Sharpness

The beam pattern determines safety. A proper low-beam pattern should have a distinct “step” or “Z-line.” It should be lower on the left side (in right-hand traffic countries) to avoid blinding oncoming drivers, and stepped higher on the right side to illuminate road signs and pedestrians. Only projector lenses can achieve this with absolute consistency. If an LED upgrade cannot produce a sharp cutoff, it is dangerous.

3.3. Thermal Management (Active vs. Passive)

High-output LEDs generate significant heat. If this heat is not dissipated, the LED chip will rapidly dim or fail.

- **Passive Cooling:** Uses large aluminum or copper heatsinks or braided ribbons. Reliable, but limited in how much power they can handle.

- **Active Cooling:** Uses high-speed micro-fans (hydraulic or ball-bearing). This allows for higher wattage and brighter output but introduces a moving part. High-quality units use robust fans designed for the engine bay environment.

3.4. Color Temperature (Kelvin)

While many chase the cool blue look of 6500K+, the most effective light for human vision at night is between 5000K and 6000K (pure white daylight). Going too blue (over 6500K) actually reduces visibility in rain and causes eye fatigue. For fog lights, lower temperatures like 3000K (golden yellow) are often preferred as yellow light wavelengths refract less in moisture, cutting through fog better.

4. Installation and Maintenance Brief

Modern advancements have made attaining projector-level performance easier than in the past.

Installation: Previously, getting a projector beam meant “baking” your headlights open and physically retrofitting a projector unit—a difficult and risky task. Today, companies offer “mini-projector” LED bulbs. These are complete projector assemblies miniaturized to fit directly through the standard bulb hole of your existing headlight housing. It is often a plug-and-play operation that instantly converts a reflector headlight into a projector headlight.

Maintenance: The most critical maintenance step is often overlooked: the outer headlight lens. No matter how sophisticated your internal LED projector is, if the outer plastic lens of your car’s headlight assembly is cloudy, yellowed, or oxidized, it will diffuse the light and ruin the precise beam pattern. Regular polishing and UV sealing of the headlight lenses are essential to maintain tactical-level performance.

5. Frequently Asked Questions (FAQ)

Q: Will upgrading to brighter LEDs blind other drivers?

A: If you use a standard LED bulb in a reflector housing designed for halogens, yes, it is very likely. However, if you use a projector lens system (like GTR’s mini-projectors), the sharp cutoff shield prevents light from shining above the hood line of oncoming traffic, making them safer than misaligned halogens.

Q: Why do some German cars have such distinct blue/purple lines at the top of their headlight beams?

A: This is called the “colorband.” It is an optical effect caused by light diffracting over the edge of the sharp metal cutoff shield inside the projector. It is a sign of high-quality optics and a sharp focus, often seen in high-end lighting systems.

Q: Are these upgrades street legal?

A: Regulations vary significantly by region and country. In many places, modifying the primary light source affects compliance. However, from a practical safety standpoint, a properly aimed projector beam that does not produce glare is far less likely to attract negative attention from law enforcement than a scattering reflector LED drop-in.

Q: My car warns me that a bulb is out after installing LEDs. Why?

A: LEDs draw significantly less power than halogen bulbs. The car’s computer (CANBUS system) thinks the bulb has blown. You may need to ensure your LED kit has a built-in CANBUS decoder, or add an external resistor to prevent dashboard errors.

6. Why GTR Stands for Optical Precision

In a market flooded with generic rebrands, GTR has carved a niche by focusing intently on optical engineering rather than just raw wattage. GTR understands that the ultimate goal is not just brightness, but the *control* of brightness.

Their development of mini-projector LED technology directly addresses the flawed nature of standard reflector housings. By supplying the entire optical stack—chip, bowl, shield, and lens—in a single compact unit, GTR ensures that the light output achieves the kind of rigorous, defined standards one might expect from top-tier precision engineering disciplines. They provide the tools to turn standard vehicle headlights into precision instruments of visibility.